By Mike Paleo & Alex Foley

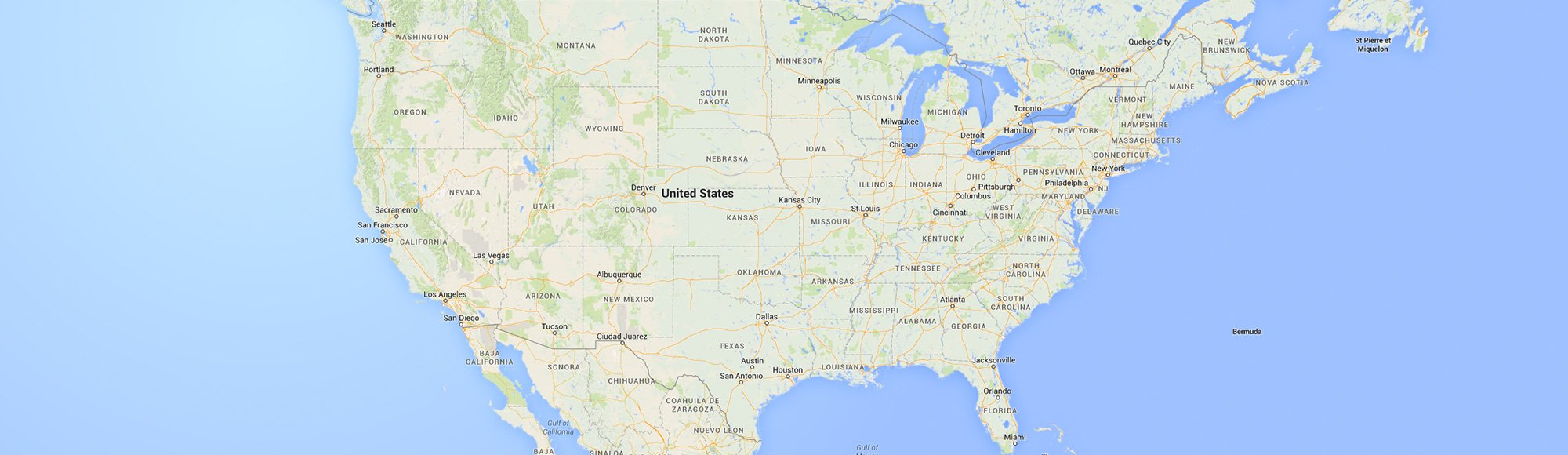

Selecting the perfect warehouse location is a multifaceted endeavor that goes far beyond typical space considerations. Whether you’re embarking on a lease agreement or making a long-term investment in a property, warehouse site selection is a critical component of your company’s competitive advantage. A comprehensive supply chain model encompasses all possible flows and facilities. Additionally, it will present various network configuration options, highlighting those with the lowest costs, enabling you to select the most suitable one for your business needs.

At Hughes Marino, we have identified five critical factors to consider when performing a site selection analysis to identify the right industrial warehouse for your business. Proximity to suppliers and customers, consideration of access to transportation networks, the regions availability of a skilled workforce, and real estate costs and availability must all be considered.

- Proximity to Suppliers and Customers

Choosing a location that is strategically positioned near your suppliers and customers can yield significant benefits in terms of reducing transportation costs, improving delivery times and fostering stronger relationships with key stakeholders.

A warehouse’s location impacts a business’ success across a number of measures—and one of the key considerations is the proximity to a business’ customer base and suppliers. In the era of instant gratification, which has driven the need for next-day delivery, customers expect fast turnaround on orders, and meeting those expectations requires strategic planning when it comes to selecting a warehouse location. Time and transportation requirements will drive up costs as well—so decisions around location need to consider the ease with which goods can be transported in and out. If goods are typically being moved via ship, a port-adjacent warehouse may be ideal. For businesses delivering goods and fulfilling online orders to inland markets, proximity to a major parcel transit hub like the Memphis Intermodal Facility or DFW International Airport will streamline operations. Other considerations that can impact shipping times include proximity to carriers with terminals and, if that’s not possible, easy access to major highways. As part of this consideration, a business should make sure to take into account the local weather patterns and risk of natural disasters, and how those events will impact operations and their ability to deliver on-time.

- Workforce Availability and Labor Costs

A skilled and reliable workforce is critical for the smooth operation of any warehouse facility. Assessing local labor market dynamics, including availability, skills and associated labor costs can help ensure that your staffing needs are adequately met.

Understanding the warehouse’s workforce needs and ensuring that it is located in a market with a high number of skilled job candidates is key to a business’ long-term success. A state-of-the-art facility is of no value if there is nobody operating within its walls. Infill locations will ensure a larger local talent pool and proximity to transportation hubs, but typically demand increased rental rates, often time for older less superior product. It’s important to note that it’s increasingly challenging for businesses to find and retain skilled warehouse employees, especially since Covid, requiring not only considerations around location but also a willingness to offer competitive wages and other perks—including flexible schedules and benefits. If locating further from an urban center is the best option to reduce lease costs, businesses must consider how they will get workers to the site—and can look into employee perks such as public transportation allowances or commute rebates.

- Access to Transportation Networks

Efficient access to transportation networks, including highways, railways, airports and ports, is essential for facilitating the smooth flow of goods in and out of your warehouse. Evaluating factors such as traffic flow, transportation costs and proximity to major hubs can help optimize logistics operations.

Understanding the geographical distribution of your customer base and suppliers can help optimize inventory management and distribution strategies. Accessibility to transportation infrastructure, including roads and highways, is crucial for ensuring efficient inbound and outbound logistics. Factors such as traffic density, congestion patterns and road quality should be carefully evaluated to minimize transportation costs and delivery delays.

- Real Estate Costs

Real estate costs vary widely depending on factors such as location, property size, age and market demand. With high-cost, port-close markets like Los Angeles commanding higher rates, your team can consider more outskirt markets with newer and improved warehouses like the Inland Empire.

In practice, companies often have specific requirements that must be considered as constraints in the supply chain network optimization process. These constraints can include limitations on the number of facilities or annual step costs that remain fixed within certain ranges. Intentional supply chain network optimization aims to identify the best combination of factories and distribution centers to efficiently meet supply and demand while minimizing costs.

It’s also important for companies to consider the potential government incentives and tax credits available to new entrants to a market. Many states will offer hefty incentives to lure a business across state lines. These incentives can be significant and in many cases the state will not only offer tax credits, but sometimes they will even source the land and fund the construction of facilities.

Conducting thorough research and financial analysis can help identify cost-effective options that align with your budget and operational requirements. Comparing buildings and different markets from a total cost perspective helps accounts for the hidden costs, such as inventory and franchise taxes, as well as incentives that can offset those costs, including local tax benefits designed to attract new businesses.

- Building Availability and Expandability

Ultimately, a warehouse is a critical part of a business’ long-term strategy. If there are plans to expand and grow in the near future, it’s important that the warehouse can accommodate that growth. Businesses need to have a plan for their next phase. If expansion isn’t possible on-site, for instance, they can ensure that there’s alternative space nearby to accommodate growth, so that if moving is necessary, the business can retain its workforce and make a smooth transition.

The ability to scale your business over time is directly impacted by the availability of suitable buildings. For instance, securing a facility in a prime location can enhance proximity to both customers and suppliers, optimizing operations.

However, envisioning the future, imagine your operations doubling in five years, necessitating additional warehouse space. If your initial warehouse choice was in a highly competitive area with no available expansions, significant logistical challenges arise, requiring a complete reevaluation of location selection. This isn’t to dissuade from competitive market choices, but rather to underscore the importance of considering long-term implications in warehouse site selection.

Depending on your business’s import/export requirements, proximity to transportation hubs such as airports, railway stations and ports may be advantageous. Additionally, operating within a foreign trade zone (FTZ) can provide benefits such as duty deferral, tariff relief and streamlined customs procedures.

Why Tenant Representation is Crucial

In addition to all the important considerations noted above, it is critical for businesses to leverage a tenant representation team that specializes in the industrial sector to secure a real estate outcome with the client’s best interest in mind. The industrial market has distinct specifications unlike the other asset classes. Hughes Marino specializes in assessing all the technical prerequisites needed to locate the optimal industrial space tailored to each client’s unique needs. Our experienced team knows the questions to ask, the critical requirements and the conditions to be aware of when identifying the right space for your facility. Whether you’re leasing, renewing, expanding, contracting, consolidating, subleasing, buying a building or building a space from the ground-up, our team at Hughes Marino is committed to your success.