La Jolla Pharmaceutical Company’s (LJPC) 83,000 square feet of engaging office and cutting-edge lab space was built, redesigned and furnished in seven months. The LJPC Project team implemented unconventional strategies to complete the innovative and creative environment that is in operation today. This in-depth case study highlights the processes and strategies implemented during the LJPC Tenant Improvement that ensured a successful construction project outcome and helped the Project receive the ENR Award of Merit for Southern California’s 2018 Best Projects.

Early implementation of creative strategies ensure positive project results.

About the Project

Starting with “Why,” the reason for the move was to co-locate multiple local offices under one roof. Here’s a brief summary of the project program:

- The team wanted to create a workplace that exuded their company culture and creatively interconnected their business strategy with their team’s social and cognitive characteristics.

- LJPC wanted roughly 83,000 SF of space that could support two-thirds office and one-third lab space built to BSL-II and cGMP requirements.

- Additional spaces desired were various lab types and hazardous material and lab equipment requirements including lab casework. (Due to proprietary reasons we refrain from divulging additional information).

Defining a Successful Project

We kicked off the project with a Visioning Session with the purpose to gain intimate knowledge of LJPC’s culture, understand the financial goals and to determine the target milestone dates. These three factors created the equation for a successful project:

Finish on Time + Workplace Design as a Strategy + Meet the Budget = Successful Project

Finish on Time

Similar to most relocation tenant improvement projects, the completion date was driven by the Lease Commencement date and potential hold-over penalties on their existing spaces. However, this project’s schedule had two unique characteristics:

- LJPC could not fully commit to finishing the project until they received positive clinical trial results.

- Halfway through construction, one of the buildings LJPC occupied was purchased, resulting in a substantial increase to their hold-over penalty and the option to extend their lease term was revoked.

The conventional project schedule targeted a start of construction in March, however, the Trial Deadline and notion to preserve capital until positive results were received pushed the construction start date to April. So, while the expected timing of the clinical trial results and responsible directive to delay capital spending understandably compressed the construction and procurement schedule, these factors didn’t make completing the project by the Lease Commencement date impossible.

In an effort to stack action items and expedite the material and procurement process, the project management team and general contractor, Rudolph & Sletten, targeted trades that included long lead time material and equipment procurement items. Although the subset of trades was small, their scopes of work accounted for roughly 55% of the total project budget. Those trades were the mechanical, electrical, plumbing (wet and dry) and fire protection contractors. Two months ahead of the Trial Deadline, we competitively bid partial Construction Documents, accompanied by a detailed Basis of Design, hired the subset of subcontractors and worked to approved submittal packages for long lead time equipment so we would be ready to place the orders the day positive results were received.

During construction, Hughes Marino, along with the general contractor, Rudolph and Sletten (R&S), and the project architect, McFarlane Architects (MA), unofficially implemented “daily huddles.” The Hughes Marino project manager would call the R&S superintendent and project manager each morning to ask one simple question, “Is there anything in your way from finishing your tasks today to remain on schedule?” As LJPC’s representative, the Hughes Marino project manager had the means to give or get direction quickly. Similarly, the MA’s project manager would speak with the R&S superintendent and project manager daily to review and answer questions in real time pertaining to field conditions or Requests for Information.

Workplace Design as a Strategy

The La Jolla Pharmaceutical Company Project Team understood several important facts. First, the design industry is living through the greatest shift in using design features to impact communication, efficiency and productivity within the workplace. Undeterred by the tight deadline, the project team’s collaborative effort resulted in making swift and successful design decisions that had far-reaching effects on LJPC’s dynamic workplace environment. For example, the team designed an open office space function void of private offices but with plenty of conference spaces of varying sizes. The conference rooms were placed at the perimeter of the building to capture the beautiful surrounding views.

Second, in today’s economy, the workforce has never had more options. So how do you attract and retain future and current employees’ attentions without sacrificing fiscal responsibility? For example, rather than act on the idea to install a refurbished Airstream on the third floor, the team reallocated those funds towards further enhancements and to bolster the audio visual features in the break room creating an engaging atmosphere and foster a dynamic space where employees operating in different departments can meet, greet, eat and interact with one another. The break room, which is the building’s focal point, also doubled as the mass gathering space for the 300-employee firm.

Lastly, my personal favorite strategy, the team made forward-thinking decisions to implement design features that would be relevant at the time of occupancy, not at the time of design. Think about it–projects of this size and magnitude take at least one full year to design, engineer, permit, and build. It is a fact in today’s environment that the pace at which design features become irrelevant or standard is faster than ever before. What a firm designed yesterday becomes a staple requirement for every new-age firm going forward that is willing to push the limits.

The La Jolla Pharmaceutical Company Tenant Improvement Project successfully deployed these tactics while meeting the budget and schedule goals.

Meet the Budget

Contrary to traditional belief, you can create a preliminary budget and schedule with only initial programming information. Despite different lab types and utility requirements and the varying interior design aesthetics, a thorough programming document would outline the lab types, utility requirements and provide a narrative explaining the intended office space design. For example, are we building basic office space, or using Pinterest as our design resource?

As I had previously mentioned, it takes at least one year to design, engineer, permit and build a project of this scope and magnitude. To add to that, a project of this size will have a hefty price tag that occupies a fair amount of the firm’s Annual Budget. So after the budget is approved and inserted into the Annual Budget, what’s next and how does it relate to the schedule? While the project schedule establishes discipline to the process across all trades and consultants, the approved budget creates a financial roadmap. When you combine both, you establish a cash flow projection that evaluates and times risk.

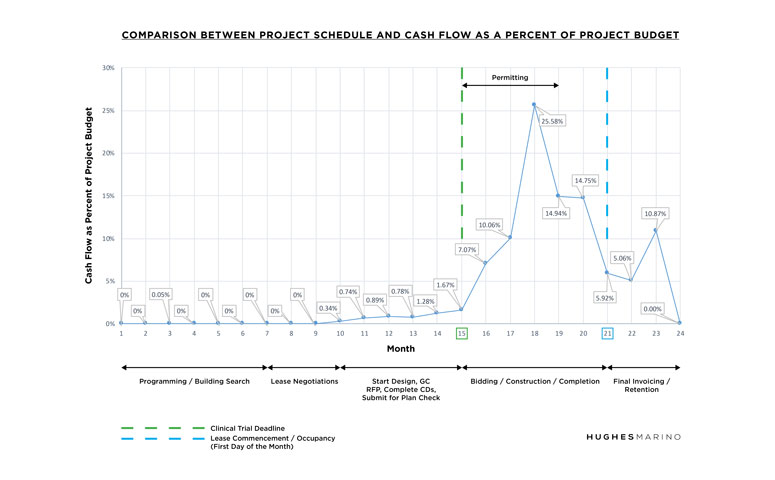

A graphical analysis comparing project schedule to cash flow as a percent of the total project budget helped Hughes Marino and the La Jolla Pharmaceutical Company to evaluate which scopes of work could be completed before the trial results, how much money to allocate for each task, and if those tasks could be deferred until after the trial results without sacrificing the completion date.

While the numbers exclude security deposits, the graph is a simple but impactful tool that remained static throughout the project and gave LJPC the ability to manage internal financial resources.

The End Results

La Jolla Pharmaceutical Company moved into their new headquarters two days ahead of schedule and within 5% of the originally approved project budget. While the end result was successful, taking the time to analyze what could we have done differently and what was done right, without dwelling on mistakes, creates valuable lessons learned that can be applied towards the success of future opportunities. One characteristic that encouraged the successful outcome was the team’s consistent effort and drive to establish a team atmosphere despite the lofty task at hand. As time progressed, the group remained focused on key strategies and processes that gained maintained momentum and alleviated pitfalls in order to deliver the successful result for the La Jolla Pharmaceutical Company.

Hughes Marino’s industry leading Construction Management team has unmatched expertise in every type of commercial building project from tenant improvements to ground-up build-to-suits. With decades of experience in California and beyond, our project managers, engineers and LEED APs offer practical insights for the construction management professional.