During a meeting with a leading life science company, these words brought an entire design team to a standstill: “I need a creative lab space that’s efficient and flexible. What are we going to do to make this happen?” Challenge accepted.

Managing the entire design process to create creative yet functional spaces is our specialty, and the Hughes Marino team whole-heartedly accepted the challenge.

Putting creative into an office space, however, is easier than inserting flexibility and efficiency into a lab space. Lab spaces are filled with dry and wet utilities, and functional requirements that make flexibility a tougher task.

So, before we could propose what we were going to do – we needed to understand why. We started by familiarizing ourselves with the company’s processes. We questioned every room’s purpose and the reason for its location. We focused our efforts on three areas: cold rooms; lab casework; and the mechanical, electrical and plumbing infrastructure.

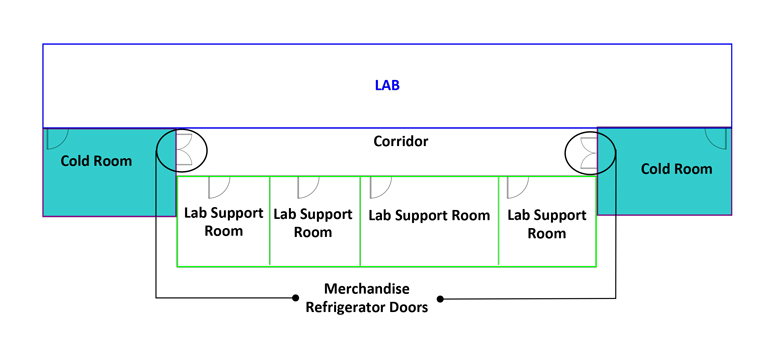

Cold Room Access

Access to and from the cold rooms can be a nuisance, due to the heavy doors. The thresholds at the doors create a stumbling barrier, and the hard walls create safety concerns.

To tackle this, we recessed the thresholds into the concrete, creating a simple fix for the tripping and barrier concerns. The access and safety concerns were resolved simultaneously – the cold room doors were accessible from the labs (where agents are prepared in small amounts).

At an adjacent wall, we cut out an opening to install merchandiser refrigerator doors. By removing the back panels of the refrigerators, the shelving became accessible from within the cold rooms, and made the refrigerator glass doors accessible from controlled corridors outside the rooms, which lead to adjacent lab support rooms. The glass doors provide transparency into the cold rooms – mitigating safety concerns.

Modular Lab Casework

For scientists, research is not a static exercise – it demands flexibility and creativity. As scientists conclude their research, new questions may demand a revised lab layout to accommodate new efficiencies, or new utilities.

For lab owners, flexibility refers to innovation, and innovation is a key building block in establishing a strategic approach in creating new wealth, managing human capital, and sustaining through turbulent economies. This notion turned our focus to the flexibility of the lab casework.

By removing sinks at benches, creating quick utility disconnects at the top of the lab benches, and putting under-counter files boxes on wheels, we could accommodate the entire lab. At the ceiling, we designed prefabricated panels for the above-ceiling utilities to terminate to outlets, or twistlocks where utility cords could quickly connect with other ends, and similar outlets or twist locks at the top of benches. The cords also allowed the benches to be located within a specific radius of the panels.

Mechanical, Electrical and Plumbing Infrastructure

Two initial thoughts: 1. Before the team starts design, be sure to establish budget goals. 2. The lion’s share of project costs lie in the mechanical, electrical and plumbing engineering fees, and construction costs.

We had budget goals in place early and a design team that clearly understood the goals. Well into construction documents, the lab owner had the idea to run every type of lab utility throughout the entire lab space, in case the company decided to invest in an unknown program that required a new utility. Sure, the plethora of utilities would offer flexibility, but it would be expensive. This was something the lab owner didn’t think about – he just saw squiggly and straight lines on paper.

Rather than panic, we all gathered around the budget goals and ran a simple budget exercise. This provided the lab owner with enough information to come to a decision that gave the company flexibility at a price tag his investors could stomach.

The resolution: We installed core utilities in the large, main lab to support the main product lines and core utilities. Additional utilities were put in special isolation rooms — for flexibility, where experimental programs could run on a small scale. Quick. Easy.

Challenge met.

Hughes Marino’s industry leading Construction Management team has unmatched expertise in every type of commercial building project from tenant improvements to ground-up build-to-suits. With decades of experience in California and beyond, our project managers, engineers and LEED APs offer practical insights for the construction management professional.